All-in-One Solar Kits: Components, Compatibility, and Installation Basics for New Owners

Outline

1) Why all-in-one solar kits matter and what “all-in-one” really covers

2) Core components and how they interoperate: modules, controllers, inverters, batteries, wiring

3) Electrical architecture and sizing: voltages, currents, protection, and performance trade-offs

4) Installation essentials for new owners: planning, mounting, wiring, commissioning, safety

5) Maintenance, monitoring, and a concise conclusion for first-time users

From Idea to Kit: Why All-in-One Matters and What’s Inside

All-in-one solar kits promise a head start by bundling matched parts that convert sunlight into usable electricity with minimal guesswork. For new owners, the appeal is straightforward: fewer procurement decisions, simplified compatibility, and documentation designed to work as a set. Typical bundles cover DC generation, power conditioning, energy storage (if included), and the conductors and protection needed to tie everything together. Put simply, a good kit reduces the friction between inspiration and a working system.

What “all-in-one” includes varies. Many off-grid or hybrid kits arrive with:

– Photovoltaic (PV) modules: usually 100–450 W each, efficiency commonly 18–22% at standard test conditions

– Charge controller: PWM or MPPT, sized to the array’s current and voltage

– Inverter: often pure sine wave; some hybrid units handle grid assist or generator input

– Battery bank (optional): sealed lead-acid or lithium iron phosphate, each with distinct performance traits

– Balance of system: cables with weatherproof connectors, combiners, breakers or fuses, mounting hardware, and monitoring

Why choose a kit over piecemeal sourcing? Component matching matters. For example, an MPPT controller operates within a defined PV input window (often with a margin for cold-weather open-circuit voltage), while an inverter requires battery voltage that aligns with its DC bus (12/24/48 V). Kits reduce the risk of pairing a high-voltage array with a controller that can’t safely accept it, or a low-voltage battery with an inverter that expects a higher nominal voltage. In addition, documentation, wiring diagrams, and labeling tend to be unified, which speeds installation and troubleshooting.

Kits also streamline planning. Because the array and electronics are curated, the main sizing tasks for a new owner narrow to site-specific choices:

– Energy target: daily kWh needed, considering seasonal variation

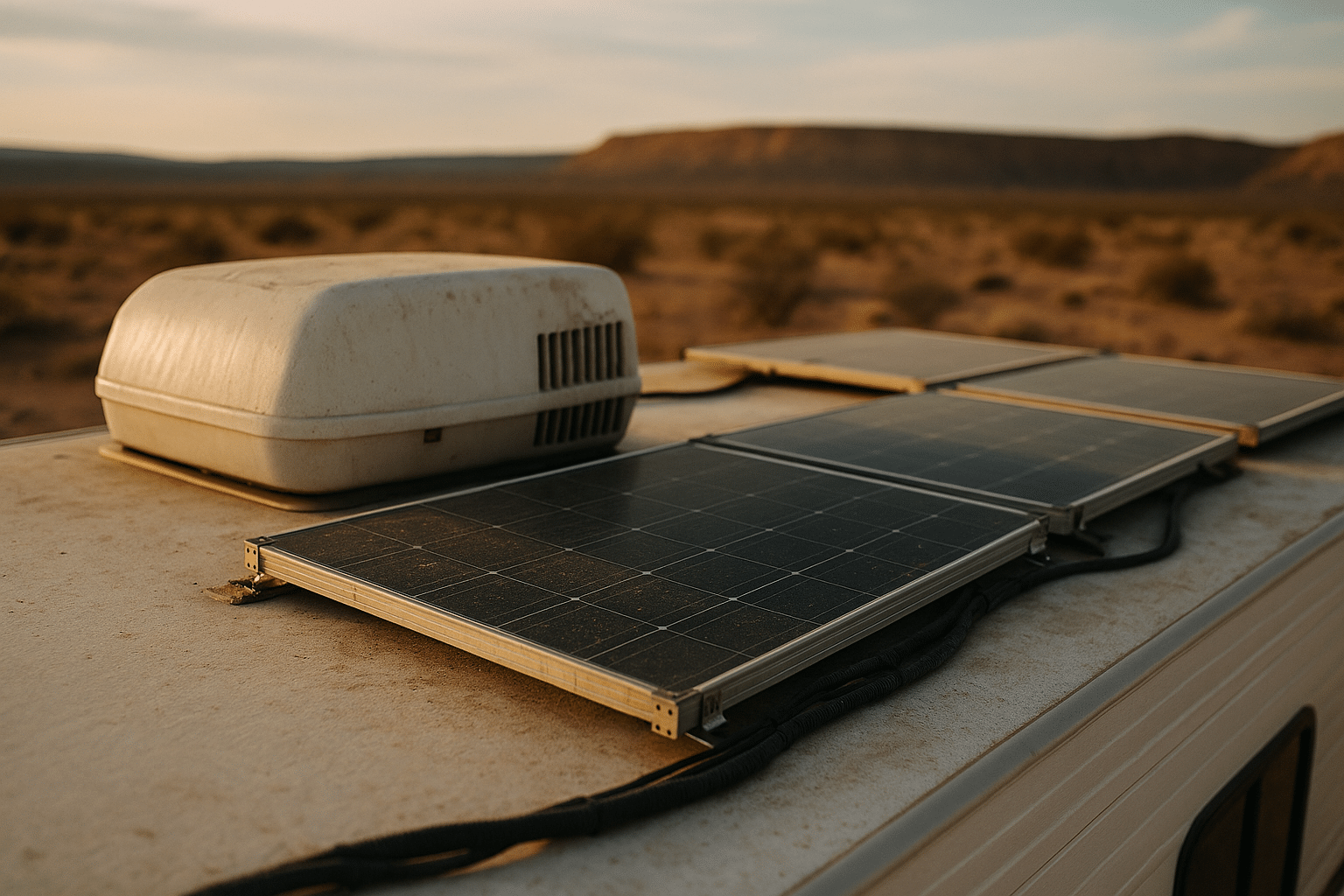

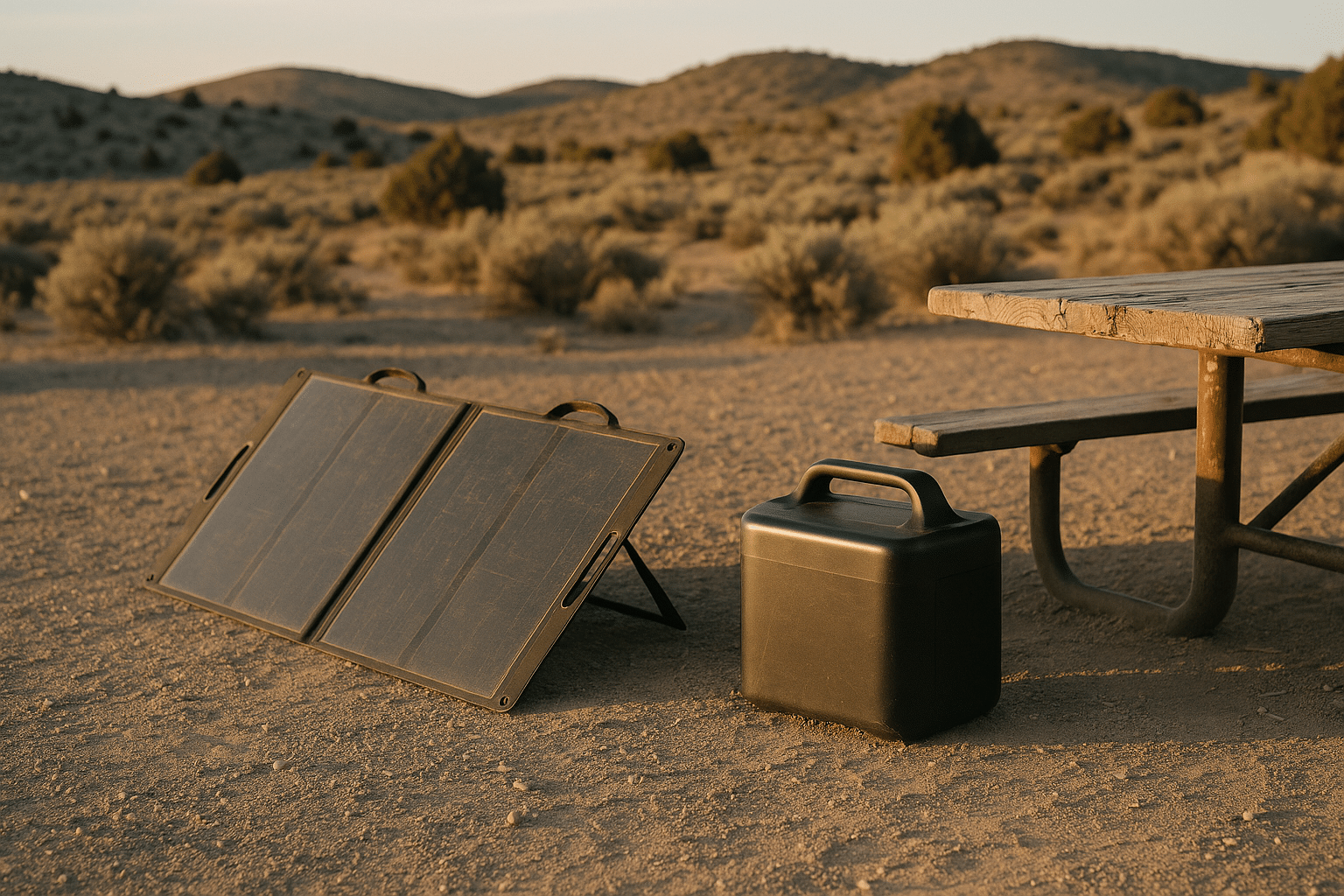

– Mounting: roof vs. ground, tilt angle near local latitude, shading analysis

– Expansion plans: leave space for more PV modules or additional battery capacity

These decisions directly influence long-term satisfaction. A carefully chosen kit can be one of the top options for a smooth first project, providing a reliable platform that’s ready to scale as confidence grows.

Component Compatibility: Making the Pieces Play Nicely

Compatibility sits at the heart of a dependable solar setup. Start with PV module voltage and current. Controllers and inverters specify maximum PV open-circuit voltage (Voc) and operating ranges; cold weather increases Voc, so designers typically include a temperature correction and a safety factor. For current, short-circuit current (Isc) informs overcurrent protection and conductor sizing, while maximum power current (Imp) guides controller selection. Within kits, stringing instructions aim to keep array voltage inside the controller’s window, enabling MPPT to operate efficiently across seasons.

Charge control choices affect energy harvest. PWM controllers are simpler and economical, but they operate the array near battery voltage, which can forfeit potential power in cooler or high-irradiance conditions. MPPT models actively track the array’s maximum power point and commonly boost harvest by 10–30% compared with PWM, especially when array voltage is higher than battery voltage. When reviewing a kit, confirm controller current ratings, input voltage limits, and whether temperature compensation or remote sensing is included for accurate charging.

Battery chemistry shapes performance and daily usability. Sealed lead-acid is budget-friendly, tolerant of cold, and straightforward, yet heavier per kWh and more sensitive to deep discharges (typical recommended depth-of-discharge around 50%). Lithium iron phosphate offers high cycle life, lighter weight, and usable capacity near 80–90% depth-of-discharge with stable voltage curves, but requires a battery management system (BMS) and compatible charging profiles. Some kits support closed-loop communication (e.g., CAN or RS485) so the charger and inverter receive precise battery status; if present, it’s a well-regarded feature for safeguarding longevity and ensuring accurate state-of-charge estimates.

Inverters must match battery nominal voltage and expected loads. A 12 V system suits modest loads and short cable runs; 24 V improves efficiency for medium systems; 48 V is preferred for higher power because conductor currents and voltage drop decline. Key parameters include continuous wattage, surge capability for motor starts, and idle consumption. Look for:

– Pure sine output for sensitive electronics

– Adequate surge (often 2x for a few seconds) for compressors and pumps

– Low standby draw with auto-sleep for off-grid efficiency

Finally, ensure conductors, connectors, and protection are coherent. PV wires typically feature UV-resistant insulation; MC4-style connectors must be mated properly; fuses or breakers should be rated for DC and sized per current with a margin (commonly 125% for continuous loads). A kit that documents wire gauges, torque specs, and protective device ratings helps new owners install confidently and safely.

Electrical Architecture and Sizing: From Roof Watts to Usable kWh

A well-sized kit turns daylight into dependable energy without frequent compromises. Begin by translating loads into energy: list appliances, their wattage, and daily runtime to estimate daily kWh. Include seasonal swings, since heating elements, refrigeration duty cycles, and daylight hours change. Add a reasonable buffer (often 10–25%) for weather variability and system losses (inverter efficiency, wiring, temperature effects). This target, not just nameplate panel watts, guides array size and storage capacity.

Array configuration depends on the controller’s allowable input voltage and power. Series connections raise voltage (lower current), which helps minimize voltage drop over longer runs and keeps wire sizes practical; parallel connections raise current (lower voltage), which can be handy when a controller has a tight input-voltage ceiling. Pay attention to temperature-corrected Voc and ensure it remains below the controller’s absolute limit on the coldest day. Meanwhile, Imp and Isc help define string and combiner protection. Many designs strive to keep voltage drop below 2–3% on longer DC runs to preserve harvest.

Battery sizing balances energy autonomy with cost and weight. For lead-acid, a common planning range is 1–2 days of autonomy at about 50% depth-of-discharge to prolong life. For lithium iron phosphate, higher usable capacity per nominal kWh and strong cycle life allow slimmer banks for the same energy target, though cold-weather charging restrictions and BMS limits must be respected. Consider charge and discharge C-rates: make sure inverter peaks and continuous demand fall within battery specifications, and verify the controller can supply recommended charge currents.

Inverter selection follows expected peak and continuous loads. A typical household circuit may see short surges from well pumps or refrigerators. Plan for:

– Continuous rating that comfortably covers concurrent loads

– Surge capability suitable for motors (often 2x for a few seconds)

– Efficiency near typical load points; many inverters are most efficient at 30–70% of rating

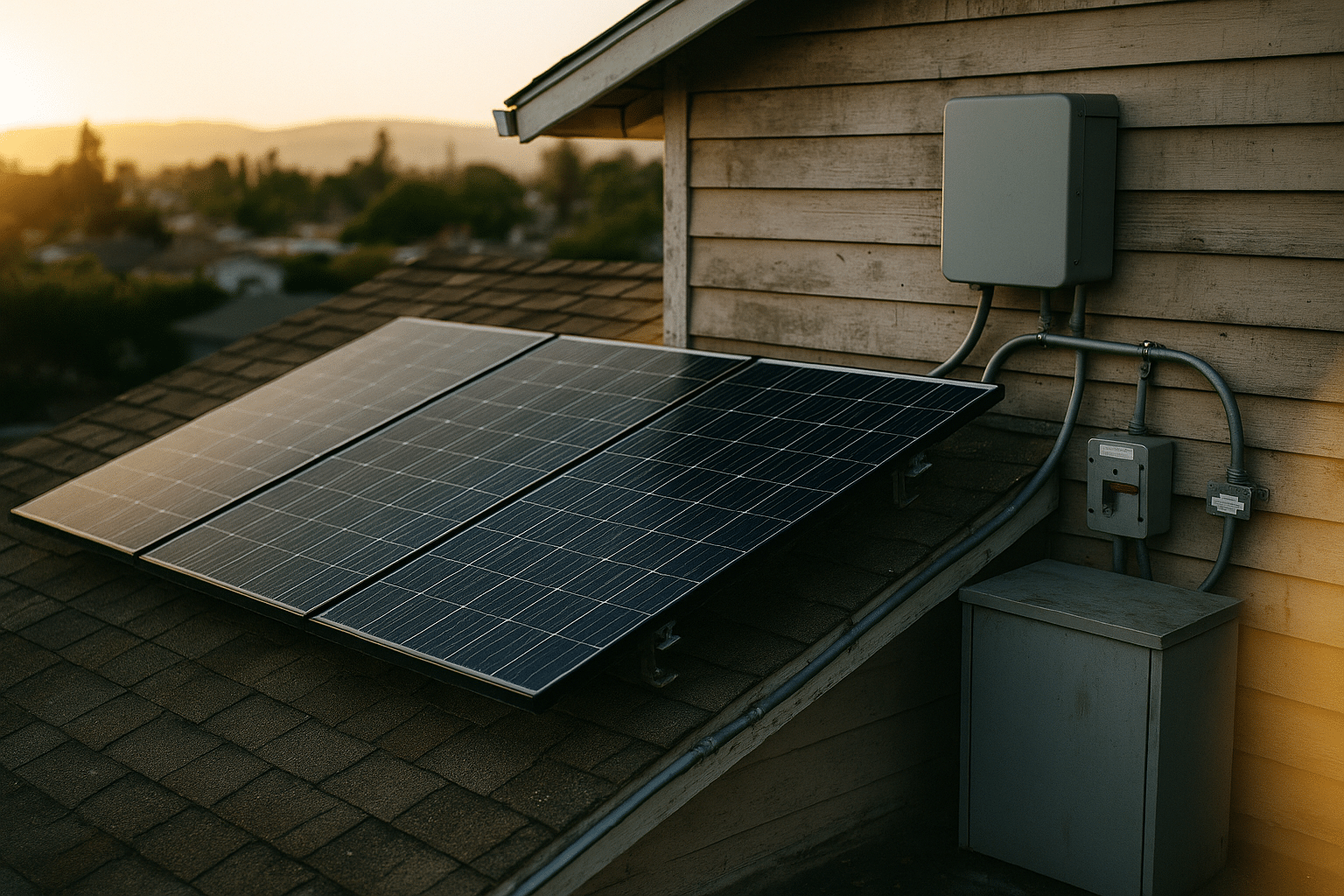

When grid support is present, hybrid inverters can prioritize solar, recharge from the grid on a schedule, and provide backup during outages, depending on local rules and wiring.

Protection and code-aligned practices are non-negotiable. Use DC-rated disconnects, fuses, or breakers near their sources; bond and ground per local requirements; and include rapid shutdown or array disconnect devices where required by authority having jurisdiction. Neat wiring, correct torque, and clear labeling make servicing safer and faster—small details that pay off for years.

Installation Essentials: Planning, Mounting, Wiring, and Commissioning

Before tools touch metal, map the project. Perform a shade study with seasonal sun paths, identify structural members for mounts, and check local permitting. Roof mounts must handle wind uplift and weather, with flashing that preserves the roof’s water integrity. Ground mounts trade roof penetrations for trenching and posts but can improve tilt accuracy and airflow for cooler modules. Aim for azimuth that maximizes production in your region; a fixed tilt near local latitude is a time-tested starting point.

Mounting hardware from a coherent kit typically includes rails, mid/end clamps, and roof attachments. Follow torque specs to avoid clamp slippage or frame damage. Maintain row spacing for airflow, snow shedding, and maintenance access. Panel-level wiring should be dressed and secured; strain relief prevents connector fatigue. When routing conductors:

– Keep DC runs as short as practical to limit voltage drop

– Use UV-resistant cable and proper clips for abrasion resistance

– Protect roof penetrations with grommets and sealants rated for the environment

Inside, locate the controller, inverter, and batteries in a clean, ventilated space protected from moisture and direct sun. Respect clearances for cooling—derating from heat can be significant. For batteries, allow space for inspection and wiring. Use appropriately rated lugs and crimp tools; torque to spec. Overcurrent devices should be clearly labeled, and disconnects must be accessible. Record serials and settings during installation—documentation streamlines future service.

Commissioning follows a deliberate order. Typical steps:

– Verify polarity on every run before making permanent connections

– Land grounding conductors and check continuity

– Connect batteries to the inverter/charger per manual; program battery type and charge limits

– Connect PV last, after double-checking string Voc against controller limits

– Power up in sequence: controller, inverter, then loads; watch for error codes

Measure open-circuit voltages, array current under sun, and AC output under a light load. Confirm that charging stages (bulk, absorb, float for lead-acid; CC/CV for lithium profiles) progress as expected. Save configuration backups if the system allows it.

Finally, safety is a throughline. Wear eye protection and insulated gloves when working around live DC. Use lockout/tagout practices during wiring changes. Respect arc flash potential on higher-voltage arrays. If interconnecting with utility service, follow local interconnection rules and hire a licensed professional where required. A careful first install turns the learning curve into confident ownership.

Maintenance, Monitoring, and Owner’s Wrap-Up

Once energized, your kit becomes part of the home’s rhythm—and a small routine keeps it performing. Dust, pollen, and bird droppings reduce output; light cleaning with water and a soft brush on cool mornings can restore lost watts. Inspect wiring annually for abrasion points, UV wear, or loose clips. Confirm torque on accessible terminals after the first few thermal cycles, then on a scheduled basis. Look for water ingress near roof penetrations and reseal as needed.

Monitoring closes the loop between expectations and reality. Many kits provide app or display readouts for PV production, battery state of charge, and load profiles. Track daily and monthly kWh to spot trends, and compare to seasonal irradiance. If yields fall unexpectedly, run a quick checklist:

– Shading changes from vegetation growth

– Connector or breaker issues revealed by unusual voltage drops

– Battery settings drifting from recommended charge limits

– Inverter derating due to heat or obstructed airflow

Batteries appreciate gentle treatment. For lead-acid, avoid chronic deep discharges and ensure full absorption regularly to prevent sulfation. For lithium iron phosphate, honor the BMS limits, avoid charging below manufacturer-specified cold thresholds, and store at moderate state of charge if idle for extended periods. Keep firmware updated where applicable; small improvements in charge algorithms can extend life and smooth edge cases.

For new owners, the journey doesn’t end at the first kilowatt-hour—it becomes a quiet craft. You’ll learn your site’s sun patterns, which loads spike in the evening, and how a cloud bank trims mid-day peaks. The payoff is practical and educational: reduced utility costs or improved resilience, plus the satisfaction of participating in your own energy supply. In closing:

– Start with a kit sized to your real loads, not just panel wattage

– Favor clear documentation and matched components over piecemeal bargains

– Leave room for expansion; tomorrow’s needs often grow

With steady maintenance and informed monitoring, an all-in-one kit can deliver outstanding reliability and a clean stepping stone to deeper energy independence.